Flame Resistant barriers WADDING for mattress

Basic Info

Model No.: mattress 01

Product Description

highloft FR Barrier Felt meet CFR 1633

Looking for a highloft FR Barrier solution?

Contact the experts at Aobo Industries for all your CFR 1633 needs.

Aobo Industries manufactures Flame Resistant barriers.

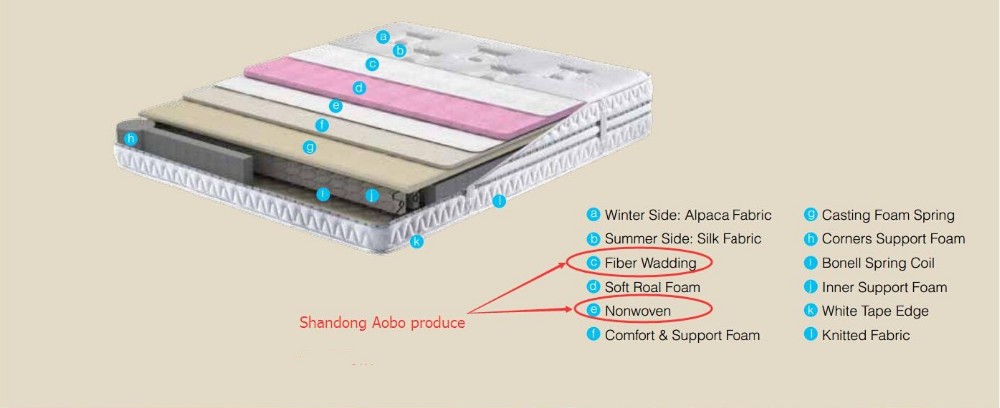

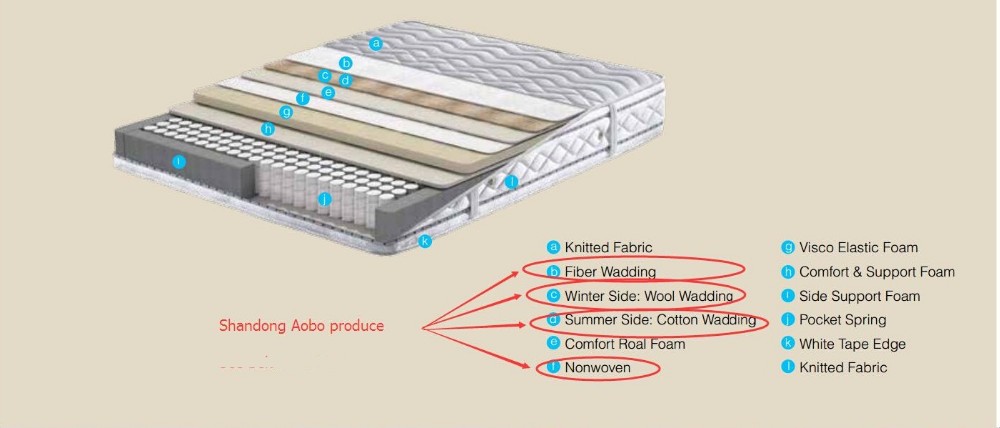

Quilted to, or placed directly under the Mattress ticking, this barrier solution is very effective at preventing flames from penetrating through to the inside mattress buildup, or fuel load.

Highloft is a dual purpose FR solution in that it also acts as a comfort layer directly under the mattress ticking. This is a safe, inherent FR solution comprised of pps/viscose,( 54556155,made from wood pulp), and silica,( 54556156,or sand), thereby posing no health risk.

We offer proven blends, 80% FR viscose 20% Binder and 65% FR viscose 35% Binder, combined with any weight that will help customers meet the mattress requirements for CFR 1633 compliance.

Application: Mattress – Comfort

Sepcification

Needle punched:

Weight is from 80gsm to 2000gsm,

Thickness is from 2mm to 50mm,

Roll width is from 1 meter to 2.8 meter

Thermal boned:

Weight is from 80gsm to 1200gsm,

Thickness is from 5mm to 120mm,

Roll width is from 1 meter to 2.8 meter

Shandong AoBo Environmental Protection Technology Co., Ltd.

Shandong Aobo produces Thermally Bonded Highloft Polyester Nonwovens, commonly referred to as "Batting". This process takes a bi-component polyester fiber (Low Melt fiber), and blends it with other matrix polyester fibers. The fibers are carded, crosslapped (layered) to a specific weight or thickness, and conveyered through a heated oven which melts the Low Melt fiber. Once through the oven the batting continues into a cooling zone which stabilizes the batting into a soft, resilient batting. Batting is then slit to width and put into roll form. Shandong Aobo manufactures polyester highloft batting with the following features and benefits:

Features:

Thermally bonded and needle punched

Fine-denier fiber blends for maximum acoustic performance

Dual density

Natural and synthetic blends

Needle punched

Fiberglass containing blends

Light weight fire barriers

Large sheets for molded applications

Cross lapping

Inline slitting

Sheeting

Large batts for molded applications

Wide width rolls up to 152"

Benefits:

Dimensional Accuracy reduces waste and additional manufacturing costs.

Flexibility in packaging allows for quicker inventory counts, quicker product identification during manufacturing and reduces quality issues.

Compression packaging allows for lower shipping costs, less warehouse space and reduces product damage.

Customization of the equipment allows customer to purchase all types and designs of batting from a single source.

Competitive costing allows customer to maintain their competitive cost advantage.

On time Delivery

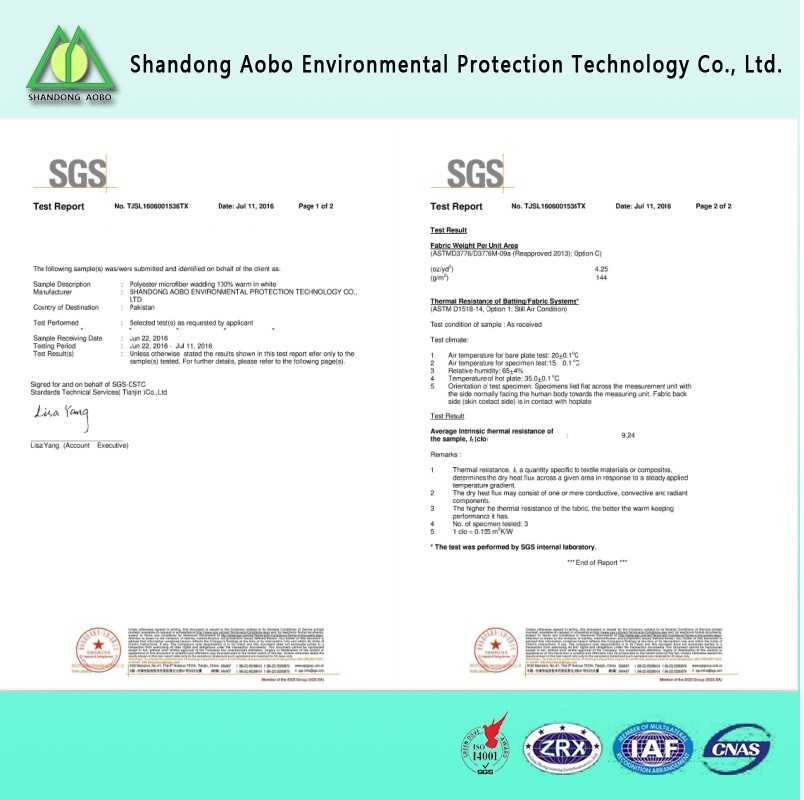

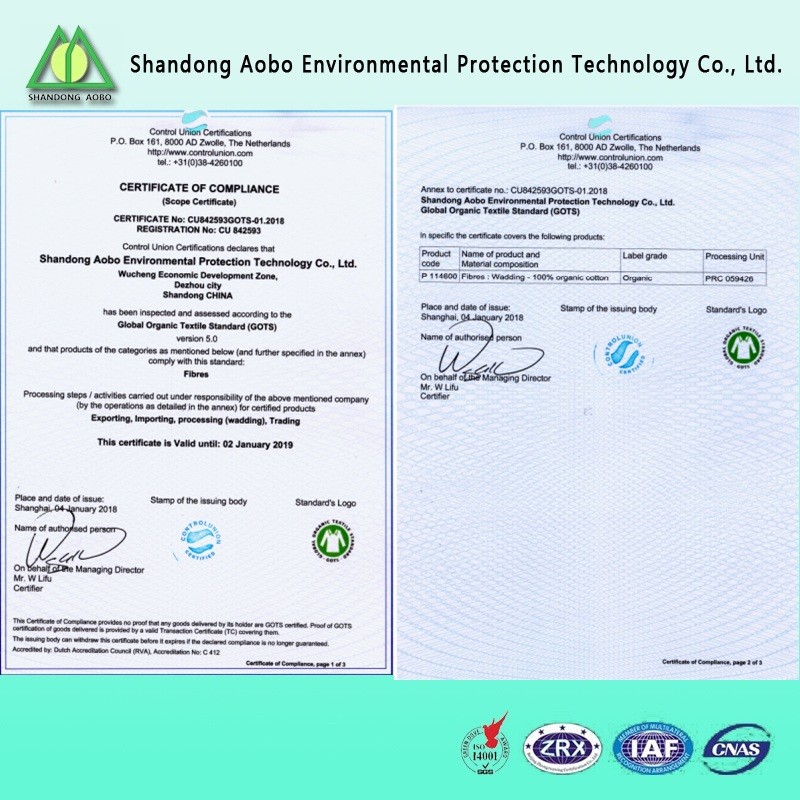

1.We are Alibaba Assessed 9 years Gold Supplier.

2.We are a factory manufacturing polyester padding,best production capability ,best quality control, Best Service .

3.Inspected by the Inspection Institution of ISO 9001:2008.

4.100% QC inspection Before Shippment.

5. ISO/UL/SGS listed,competitve price.

Sample lead time:1~7 days,

We do quotation within 2 days and welcome your any inquiry at any time.

A: Welcome any OEM requirements.

B: We offer instruction for customers to the usage of our product.

C: We offer goods return and goods exchange for reasonable situation.

D: We’ve got experts ready to solve some professional questions.

E: Professional shipping service if necessary.

F: We can produce products according to customer’s request.

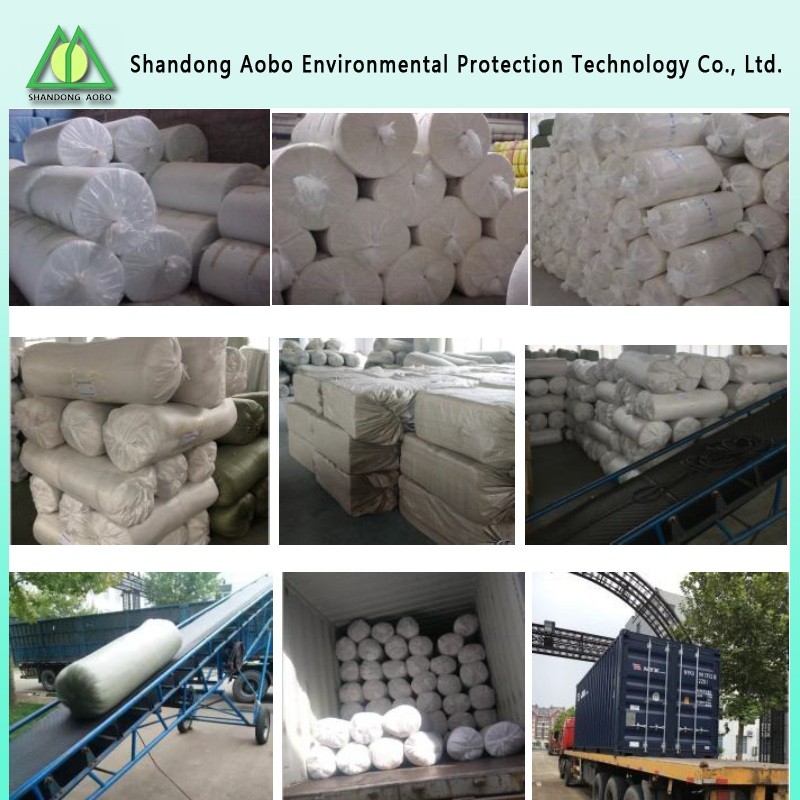

Packaging Details: inner with pp bag, outer with woven bags

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 1-7 days for samples; 7-15 days for batch goods.

Product Categories : Mattress

Premium Related Products