High temperature boiler precipitator with Ptfe be filter bag in High temperature

Basic Info

Model No.: FD-0007

Product Description

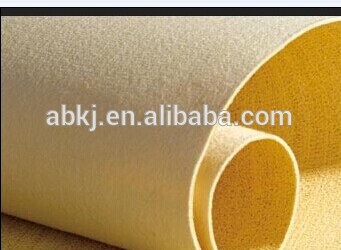

nomex Filter bag with ptfe membrane

Description

Nomex is one kind of aromatic polyamide fibers,beside with polyester fiber spinnability and the wear resistance,the biggest characteristic is to have good resistance to heat and flame retardancy and infusibility.Fiber oxygen index can be in 29%,temperature at 400 °C or more, the fiber is slow carbonization.In addition,Nomex needle Felt has good dimensional stability.Compared with glass fiber,have a more superior wear resistance, folding endurance.

Nomex is one kind of aromatic polyamide fibers,beside with polyester fiber spinnability and the wear resistance,the biggest characteristic is to have good resistance to heat and flame retardancy and infusibility.Fiber oxygen index can be in 29%,temperature at 400 °C or more, the fiber is slow carbonization.In addition,Nomex needle felt has good dimensional stability.Compared with glass fiber,have a more superior wear resistance, folding endurance.

Nomex needle felt can be continuous operated in the condition of 204°C(instantaneous temperature 250°C),also can withstand repeated 250 °C instant fluctuating temperature,In the temperature 250 °C only less than 1% of the thermal shrinkage.Good chemical resistance at a low concentration of acid, and most of the hydrocarbons does not affect to Nomex needle felt,even a small amount of fluoride won't obviously corrosion it.Long-term use Nomex needle felt also can keep high tenacity high wear resistance.

Nomex needle felt can be continuous operated in the condition of 204°C(instantaneous temperature 250°C),also can withstand repeated 250 °C instant fluctuating temperature,In the temperature 250 °C only less than 1% of the thermal shrinkage.Good chemical resistance at a low concentration of acid, and most of the hydrocarbons does not affect to Nomex needle felt,even a small amount of fluoride won't obviously corrosion it.Long-term use Nomex needle felt also can keep high tenacity high wear resistance.

Feature

1.High dimensional stability

2.Excellent resistance to high temperature performance

3.High-wearing feature and folding endurance with long service life

4.Good resistance to chemical corrosion,Acid and alkali resistant and not easily corroded

5.Fire retardant performance above 400 °C decomposition charring, limiting oxygen index (LOI) of 30, does not support combustion and not spontaneous combustion

Application

1.Blast furnace gas filter

2.Petroleum fumes air filtering

3.Coal fired boiler gas treatment

4.Carbon black plant air filtration

5.Asphaltum plant dust collection

6.Metallurgical plant tail gas treatment

7.Vertical kiln of cement plant dust filtration

8.Non-ferrous metal smelter gas processing

9.Tobacco manufacturing process gas filtration

Performance Index

Material | Nomex / Aromatic polyamide | |

Grams (g/m²) | 500 - 550 | |

Density | 0.29g/cm³ | |

Thickness (mm) | 2.0-2.2 | |

Air permeability (m³/m²/min) | 13-16 | |

Tensile strength warp (N/5×20cm) | warp | ≥1300 |

weft | ≥1480 | |

Tensile elongation (%) | warp | ≤20 |

weft | ≤55 | |

250°C Thermal Shrinkage | warp | <1 |

weft | <1 | |

Operating temperature (°C) | Continuous | 204 |

Instant | 250 | |

Filtration velocity (m/min) | 1.0 - 1.2 | |

Acid-resisting | Excellent | |

Alkali-resisting | Excellent | |

Abrasive resistance | Excellent | |

Hydrolytic stability | Good | |

Finishing treatment | Singeing,calendering or Teflon Coating | |

Perfect Service

Shandong Aobo provides solutions to its customers by supplying high quality products with strong technical support.

PRE-SALE SERVICE

Detailed, professional and complete analysis can help customers with best possible understandings of their applications and requirements. Then best-use technical solutions are provided.

SALE SERVICE

With excellent language skills, our sales people can communicate well with customers from all of the worlds.

With many years experiences of import and export, our sales people are very familiar with international trade flow. These can help customers to save cost and avoid the risk.

With high responsibility, our sales people make your prompt response anytime and help you follow up the production, packing and delivery time.

AFTER SALE SERVICE

Provide customers with technical supervision for filter bag installation.

Provide customers with regular laboratory tests to monitor system and filter bag performance.

If there is any question please kindly let me know,thank you.

Bag Erection and Storage Requirements

• Before installing filter bags the tube sheet must be checked to ensure that it is clean, there are no sharp edges and there is no debris that could eventually fall into the filter bags

• The installation procedure is normally decided on site and is dependant upon the number of personnel being used and the available access. Normally it is wise to work compartment by compartment first fitting all the filter bags.

• The filter bags fitting is simple via a snap band, no tools are required. The filter bag is lowered into the corresponding tube sheet hole and the top seal is made by forming a kidney shape in the snap band top and then releasing this into the tube sheet hole. The groove in the filter bag should fit tightly into the tube sheet forming a seal.

• This is repeated until all the filter bags have been fitted.

• Before lowering the cages into the filter bags boards or heavy cardboard should be placed over the bags to protect the filter bags and prevent them being stepped on. If the bags are stepped on they can loose the seal and cause dust emissions at a later date.

• During the installation of the cages care should be taken not to damage or bend the cages. No damaged, badly bent or corroded cages should be fitted into the filter bags.

• After all cages have been fitted, an inspection from the inside of the hoppers must be carried out to ensure that all the bags and cages are the correct dimensions and positions.

Important rules for storing filter bags.

• Store the filter bags and support cages in their original packaging.

• The filter bags and support cages must be stored in a dry area.

• Keep the filter bags away from all types of fungi, micro-organisms and insects.

• Protect the filter bags from rodents or other pests.

• Avoid loading the filter bags and support cages with other heavy objects

Product Categories : Dust collector

Premium Related Products